Green, through and through

Carbon dioxide increases have directly contributed to the climate crisis

C-Motive’s technology has lower impact on scope 2 carbon emissions

Without magnets or copper, scope 3 carbon emissions are much lower

Decarbonization

Reducing CO2 levels (decarbonization) is essential to fixing the climate crisis. Significant contributors of carbon emissions are all around us in more ways than one; while an electric vehicle may not burn fossil fuels and emits fewer carbon emissions, it could still be manufactured with materials that contribute generously to carbon emissions. Because of this, we need to dig deeper to truly make a difference in CO2 levels.

Circular Design

sustainability

Environmental & Economic Sustainability

Our electrostatic motor contributes to massive amounts of carbon savings through higher energy efficiency. By utilizing less embodied carbon within the raw materials in its production process, efficiency and carbon savings directly contribute to cost savings.

sustainability

Material use

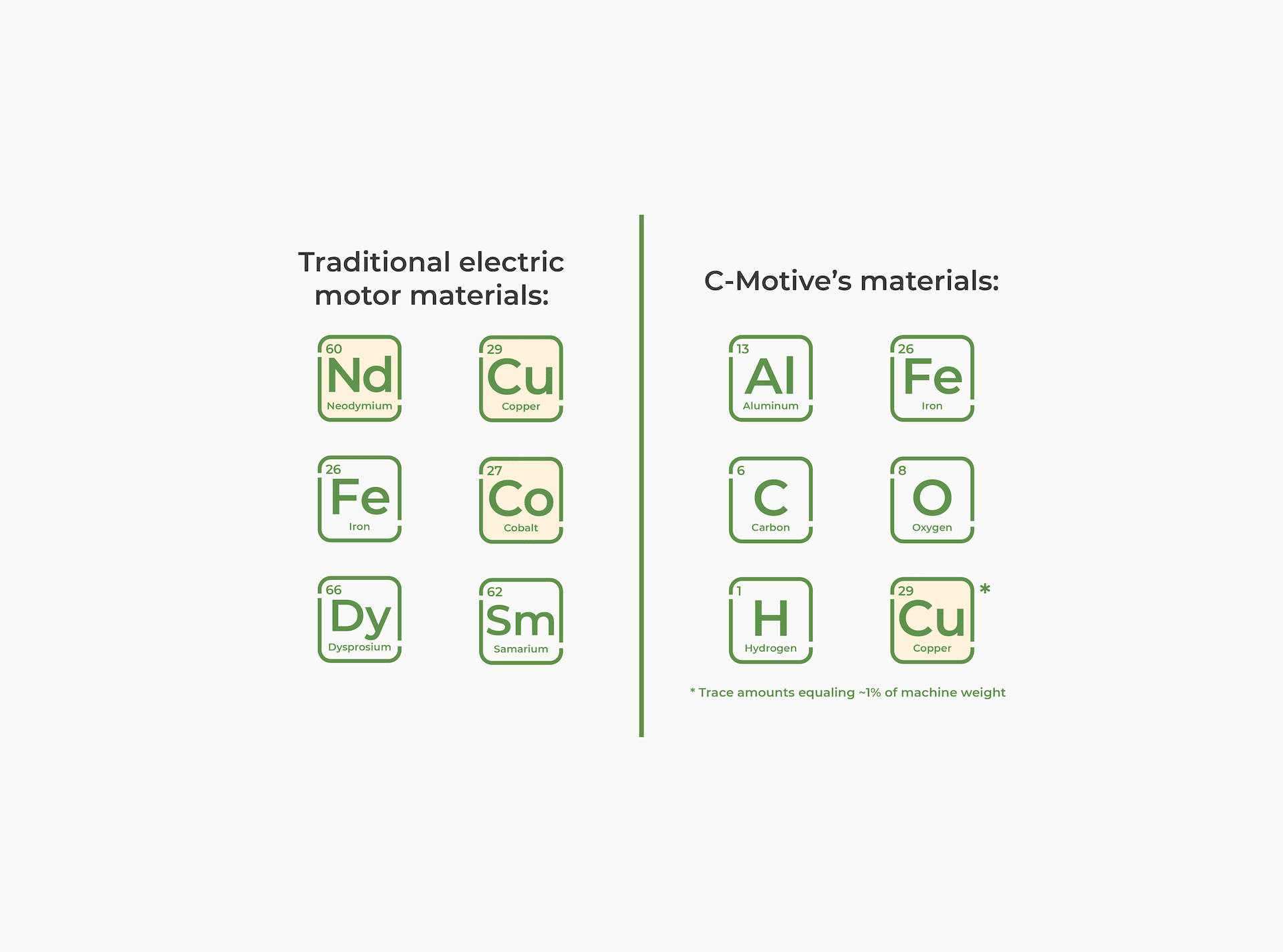

C-Motive is creating an efficient electrostatic motor that contains no permanent magnets and the same amount of copper that you would find in a handful of pennies, making our technology both environmentally and economically sustainable at the same time.

sustainability

Human & Social Sustainability

Internally, C-Motive is dedicated to supporting employees and giving opportunities to enhance skills as well as learn new practices as they continue their careers. Externally, C-Motive looks to sell products that help people around the world and use materials that don’t involve harmful mining and processing practices.

We know what we’re made of

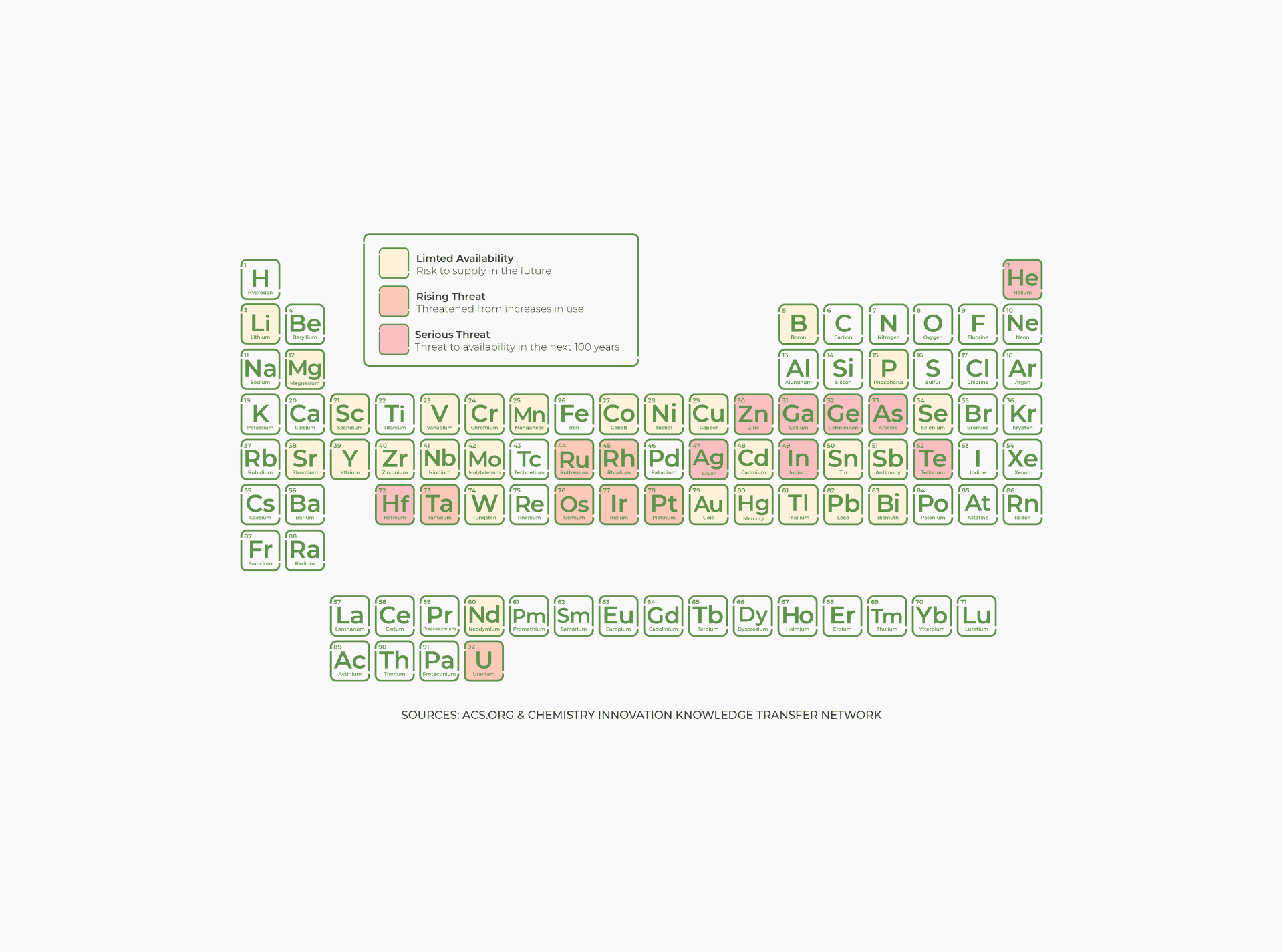

Traditional motors rely on critical materials to function

A small set of countries export critical materials

C-Motive machines use no magnets or electrical steel

supply chain

Instead of magnets, copper windings, or electrical steel, electrostatic motors use printed circuit board plates and a proprietary dielectric liquid. Both of these materials can be sourced around the world and are not reliant on a single supplier or country.

Percent of Total Machine Weight by Materials |

|||

| Permanent Magnet Motor | Induction Motor | C-Motive’s Electrostatic Motor | |

| Copper | 10% – 20% | 15% – 35% | 1% |

| Electrical Steel | 30% – 40% | 40% – 60% | 0% |

| Magnets | 3% – 10% | 0% | |